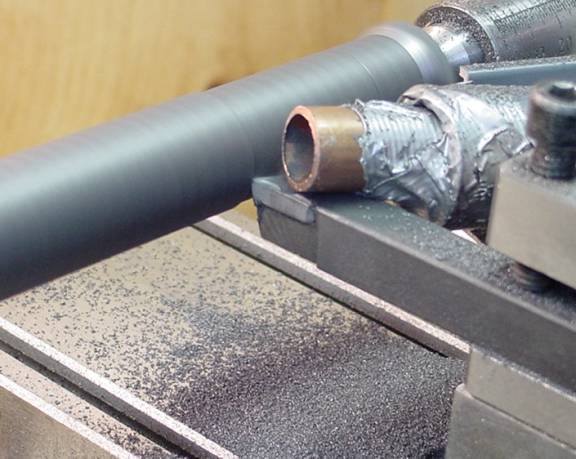

The pistons in our Stirling engines are made out of graphite.Here I show a piston being made.

The cutting tool is the gray piece coming from the lower right towards the center of the picture.The copper tube is connected to a vacuum cleaner to remove the graphite dust as the piece is machined.The piece is the gray cylinder going from the lower left towards the upper right, held in place by a dead center at the top.

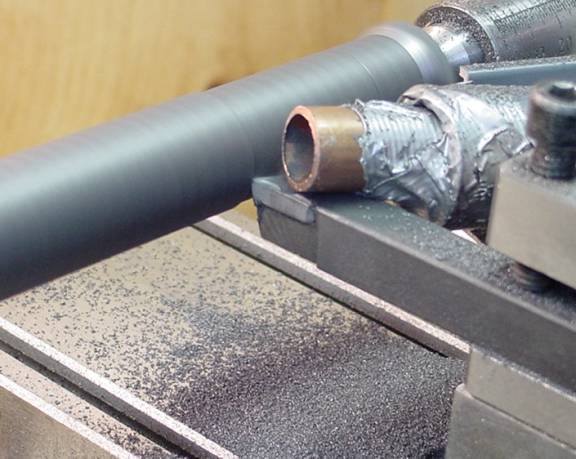

Finishing the piston, using regular paper as an abrasive.

The finished first piston.

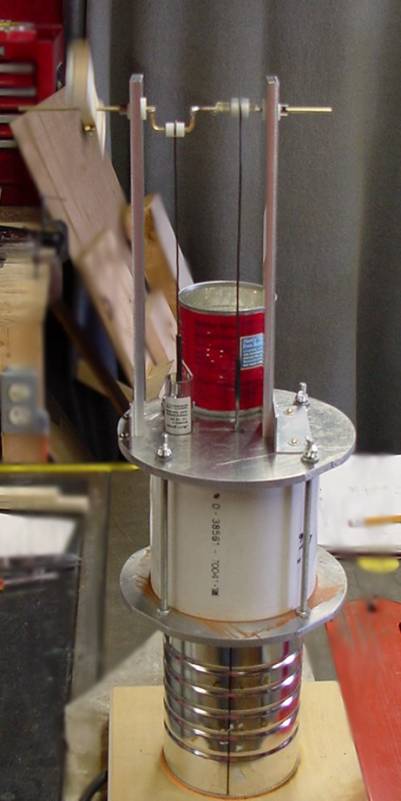

The finished Ugly One engine.The copper colored crankshaft can be seen across the top of the twin support towers. The blur on the left of the left tower is the flywheel.The two vertical black lines are the piston push rod (left) and the displacer push rod (right).The red tin can on the top was there temporarily to hold ice to cool the top of the engine.The displacer chamber is the white PVC cylinder towards the bottom.The metal can at the bottom contains a light bulb, which we used as a heater to test the engine. The redish stuff near the bottom of the engine is left-over sealant.

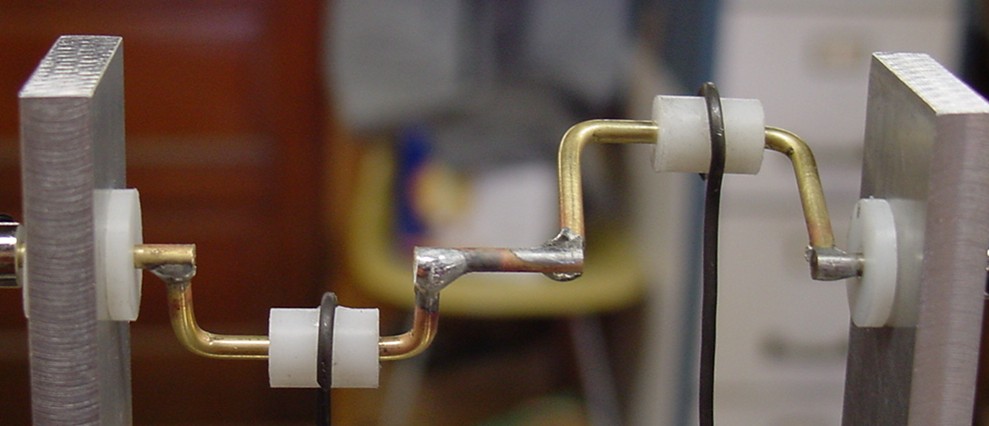

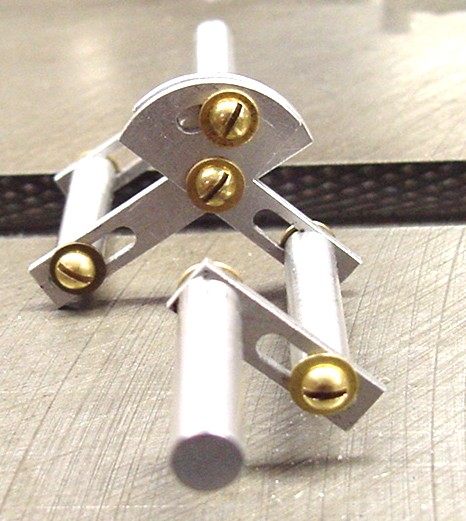

Ralph created an adjustable crank for this engine, shown below.We ended up not needing it for the next engine, but it was a piece of work.

Notice all of the various adjustments possible: both the displacer and piston throws can be modified, as can the angle between the two.

A close-up of the actual crank used in Ugly One.Ralph became very adept at this kind of soldering, which produced perfectly straight cranks.Attempts to make bent wire cranks were frustrating.