Our family has used a horizontally mounted wagon wheel as a drying rack for years. Eventually, the wheel disintegrated. I proposed to replace it with a more modern concept.

I started out with two aluminum plates, ½” thick.I had Ralph cut them into two 7” diameter disks, and I then mounted the disks on the rotary table and drilled, threaded, and bolted them together.

The disks were then re-mounted on the rotary table, the table was turned 90 degrees, and holes were drilled for each spoke.

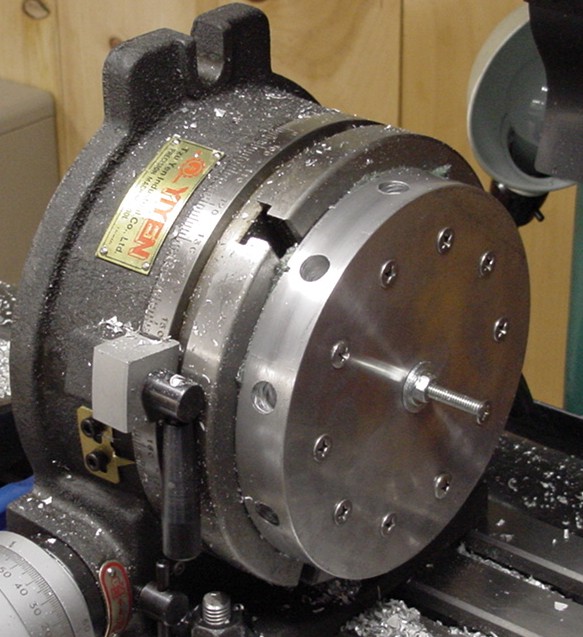

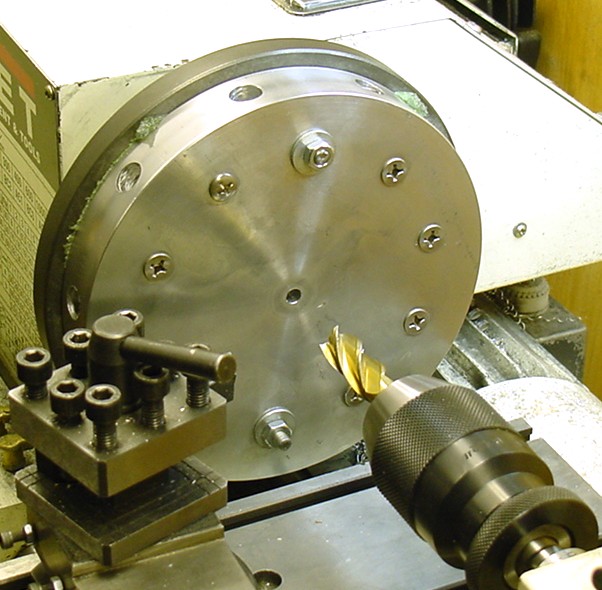

After the spoke holes were drilled, the hub was mounted on a face plate so that I could drill out the center hole on the lathe. The “strange” drill bit is in fact an end mill.

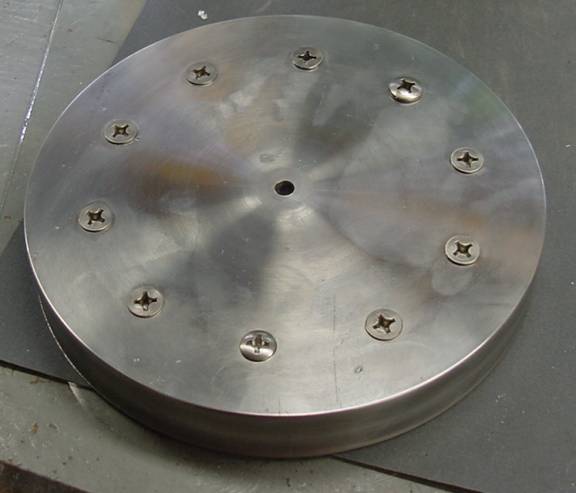

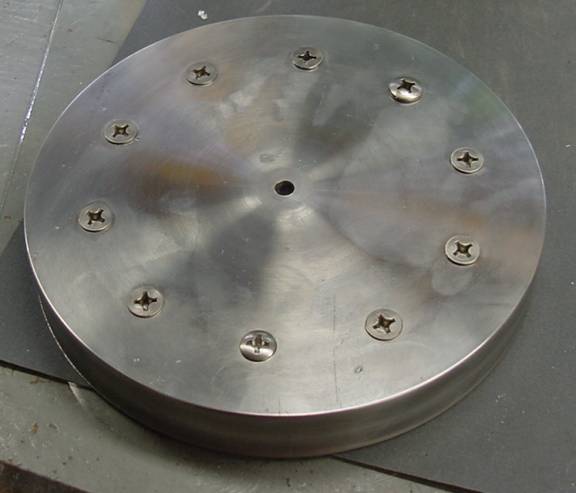

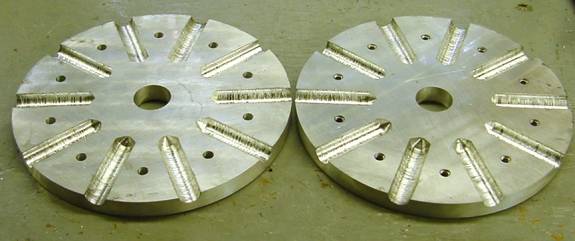

The two plates, separated, with the top on the left and the bottom on the right. Note the drilled holes which will accept the spokes.

Same as above, only showing the inside of both plates.

The spokes inserted in place on the bottom plate. They were milled down so that they would just fit when the two plates were bolted together again, so that the plates act like clamps.

The finished drying rack in place.