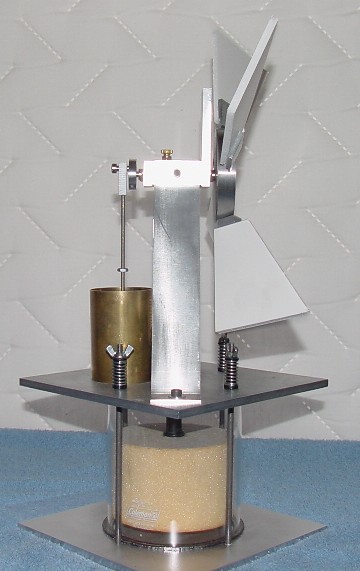

This is the first engine I build all my myself. It is based on the first engine we built, but with a new “tower” assembly. This tower is lighter, stronger, and serves as a kind of heat sink, to help cool the top of the engine. The fan blades are made out of “foam core”, to minimize damage if you get your fingers in the way. Each fan blade can be individually adjusted for angle of attack. The displacer is made of insulating foam. Some of these foam displacers have failed on top of the stove, but the most recent one has worked for weeks without a problem. The hole in the fan hub is a counter weight, which ensures that the engine never comes to rest at Top Dead Center or Bottom Dead Center. This, along with the spring which suspends the displacer in the middle of the cylinder, allows the engine to start given only a slight disturbance, once it is up to temperature.

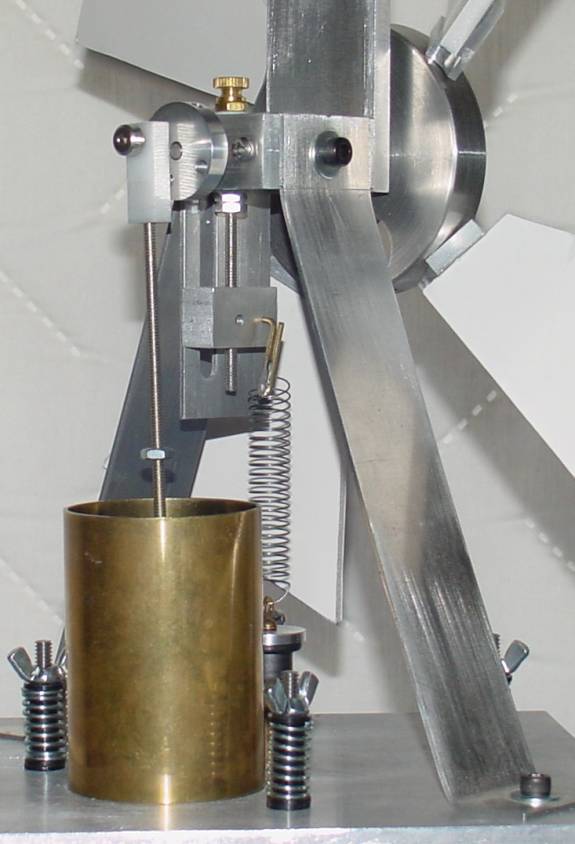

The resulting engine has a fairly clean design. Note the springs, which clamp the plates to the glass displacer cylinder. This ensures uniform pressure while also giving the glass a little room to move if it needs to. Note the grass knurled knob at the top of the tower: this allows us to adjust the vertical position of the displacer spring. In this particular configuration, the fan hub is made of steel, and also serves as a fly wheel.

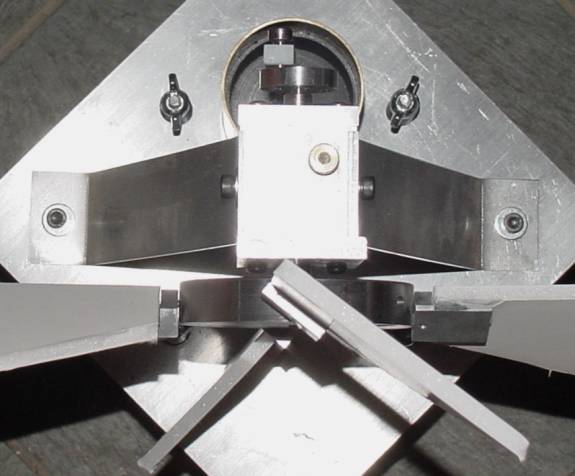

From the top. Note how the tower “legs” fit precisely into slots milled in the block at the top of the tower. This precise fit prevents the tower top from moving under pressure.

The engine from an angle.

Detail of the engine from an angle. Note the small crank wheel, with multiple holes for varying the crank throw; the adjustment mechanism for the vertical position of the displacer spring; and the hand made displacer spring (we could not find any commercial springs with the right characteristics).